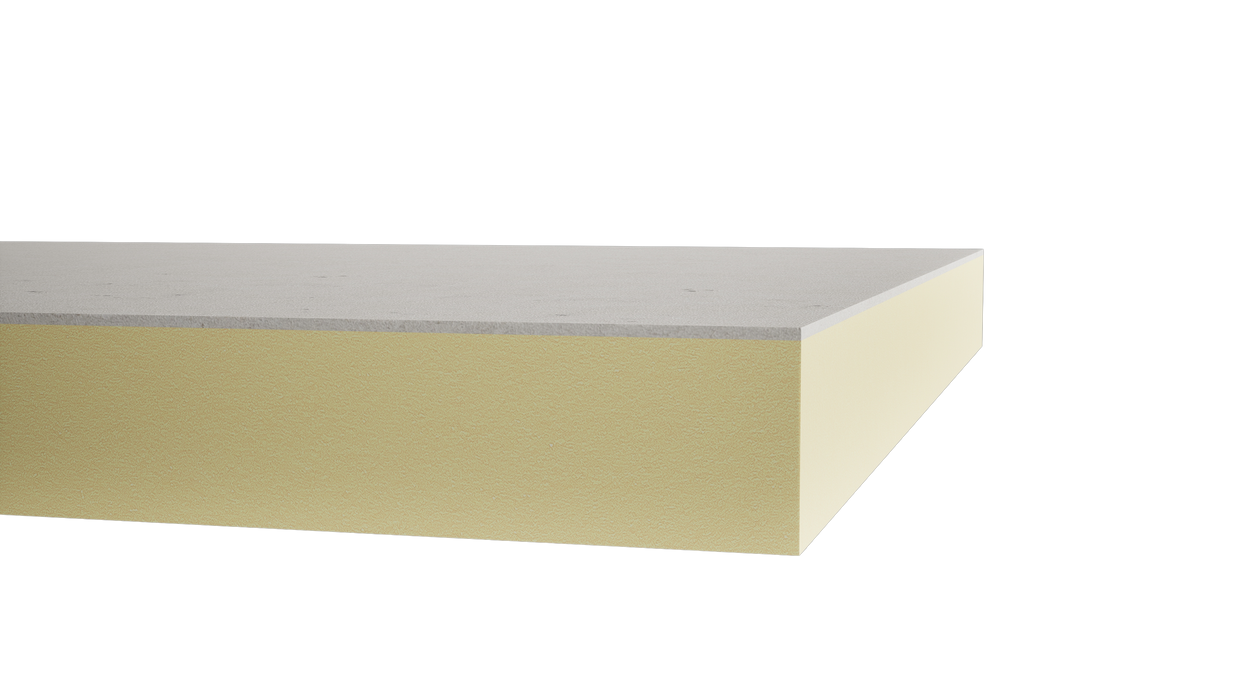

High impact cementitious faced CO2 blown extruded polystyrene

XMD boards combines the benefits of a high performance HEXATHERM extruded polystyrene with a high impact facing board to produce the ideal treatment to protect inverted roof vertical up-stands.

Architect and specifier resources

Third Party Accreditation and Approvals

Specifications

Brand name

HEXATHERM XMD

Product description

High impact cementitious CO₂ blown extruded polystyrene

Thermal conductivity (W/mK)

0.033 ≤ 80mm, 0.033 ≥ 86mm

Strength at 10% compression (kPa)

300

Strength at 2% compression (kPa)

125

Long term water absorption by immersion

<0.7%

Board size (mm)

1200 x 2400

Facing board thickness

6mm

Overall thickness (mm)

56, 66, 76, 86, 106, 126, 146, 166

High impact grey cementitious facing

Excellent life-long thermal performance

Quick and easy to install

Robust Detail and Proprietary applications

Handling and Storage

Store inside

This product should be stored inside on a pallet in water-tight conditions on a dry, flat and level base.

It can only be stored in a single lift, do not double stack.

If you are required to re-stack the product, we advise that the boards are stored on a pallet or are fully supported from the underside.

Care should be taken not to damage the edges of the board whilst re-stacking. The stacking of the product on it's edges should be avoided, as this can lead to damage.

Product protection

This product is supplied on pallets, wrapped in temporary protection. This covering is to offer dust protection and is a temporary measure to protect the boards from the weather during the loading/unloading process, it is not a waterproof cover and should be stored inside.

Adhesives and primers need to be protected from frost damage. They should be stored & used at temperatures between 5°C and 35°C and kept out of direct sunlight.

.png)